Sharp stuff! The way of the razor blade to your bathroom

Razor – if you look at the word in a historical context, it can be traced back to the Latin term rasura, which means 'the scraping, scratching, smoothing'. This sounds crude compared to today's idea of a shave, as we all know only the particularly sharp and thin blades used in modern (or not so modern) wet razors – at first glance a simple product, but behind it lies a complex manufacturing process. In this process, material, heat, coating, and also plant technology from ONEJOON play an important role.

The cut

What do crown caps and razor blades have in common? The people behind both inventions share a common history. William Painter, a native of Ireland, applied for a patent for the crown cork in Baltimore (USA). One of his collaborators was none other than King Camp Gillette. Gillette traveled the country as a salesman for Painter and dreamed of a groundbreaking invention himself. His boss, Painter, advised him to focus on a commodity – and one morning in 1895, he had an idea.

That morning, Gillette cut himself while shaving – a drastic experience that set him thinking about developing a practical shaving device. Without further ado, he tinkered the prototype of the first wet razor out of watch spring steel and sheet brass. He filed a patent for it in 1901 as the "Safety Razor". The figures speak for themselves: by 1905, he had already sold 90,000 razors and 125,000 blades.

Two New Yorkers in south Thuringia

Gillette's legacy has endured. Together with its competitor Schick/Wilkinson Sword, the razor blade giant dominates the market – and whoever dominates the market also determines the prices. The two New Yorkers Andy Katz-Mayfield and Jeff Raider wanted to break up this dominant position and bought a razor blade factory that was over 100 years old, Feintechnik in Eisfeld, Thuringia, for their project in 2014. Big Apple meets Thuringian dumplings, so to speak. As the start-up Harry's, the entrepreneurs are pursuing the goal of offering razors and blades at affordable prices through direct sales.

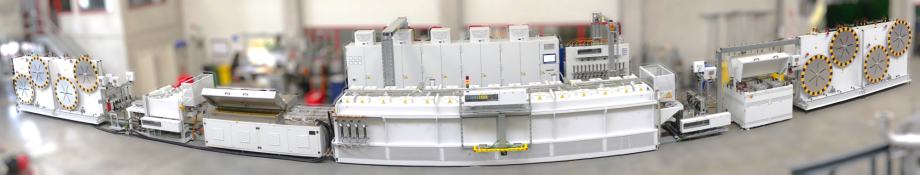

Around 600 employees now produce razor blades and shaving systems for Harry's at the Eisfeld plant. Furnace systems from ONEJOON are also located there, which brings us directly to the manufacturing process of the sharp blades. Before the blades can run gently over the skin of the face in the usual quality, there is a complex manufacturing process that consists of several steps.