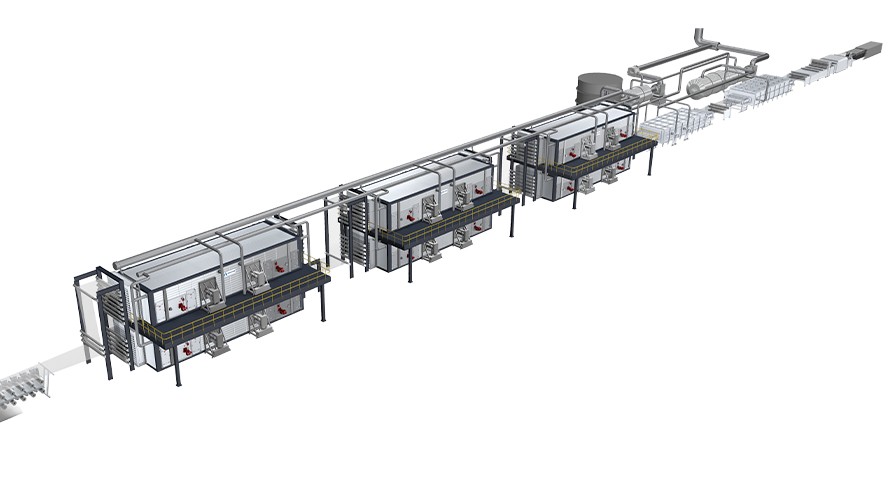

Processing Lines for the Production of Carbon Fibers

Best-in-class production equipment from the market leader

ONEJOON is the world leader for thermal processing equipment used in the production of oxidized PAN fibers, carbon fibers and carbon paper & felt. Our oxidation ovens are best-in-class and provide the innovative technologies that have been adopted by the industry. Our carbonization furnaces have been frequently installed and successfully operated in carbon fiber production lines across the globe.

With our long-standing experience and solid expertise, we are the preferred partner of well-known manufacturers and the go-to partner for new market entrants, which results in a market share of >50 %.